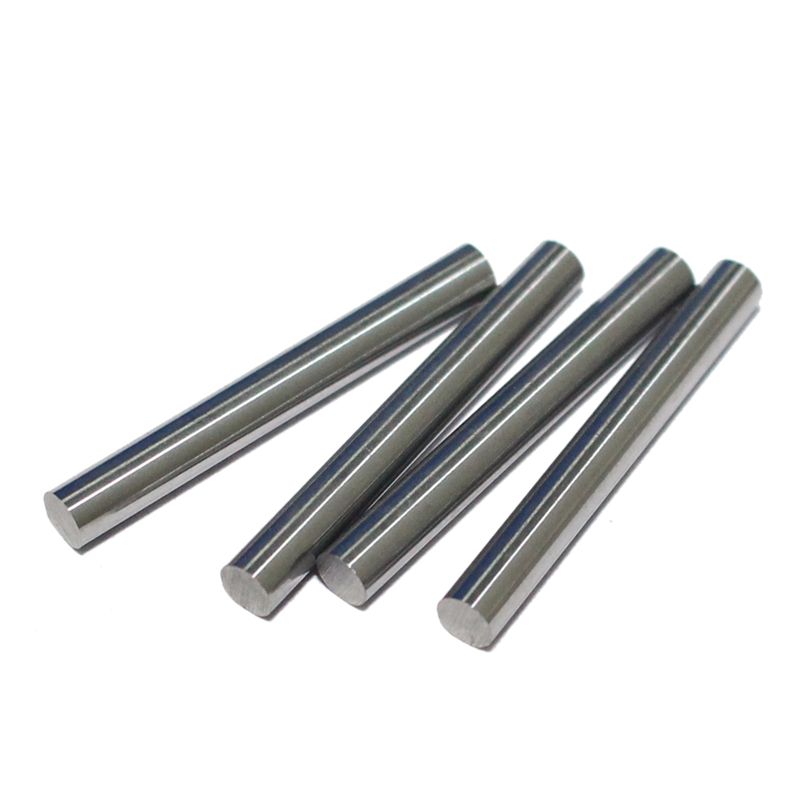

High Quality Tungsten Carbide Inserts for Industrial Applications

By:Admin

{} is a leading manufacturer of Tungsten Carbide Inserts, offering a comprehensive range of products designed to meet the diverse needs of industries such as mining, construction, and metalworking. With a strong commitment to quality and innovation, {} has established itself as a trusted provider of cutting-edge solutions for cutting and drilling operations.

The key to the success of {}'s Tungsten Carbide Inserts lies in the advanced materials and technology used in their production. Tungsten carbide, known for its exceptional hardness and wear resistance, forms the core of these inserts, providing the durability and longevity required for demanding applications. Combined with innovative design and precision engineering, {}'s Tungsten Carbide Inserts deliver superior performance and reliability in even the most challenging environments.

One of the key advantages of {}'s Tungsten Carbide Inserts is their versatility. With a wide range of insert types and geometries available, {} is able to provide solutions for an extensive variety of cutting and drilling tasks. From roughing and finishing operations to specialized applications such as thread milling and grooving, {}'s inserts are designed to excel across a broad spectrum of cutting and drilling requirements.

In addition to their exceptional performance, {}'s Tungsten Carbide Inserts are also designed with productivity and cost efficiency in mind. By optimizing cutting edge geometries and incorporating advanced coatings, {} is able to maximize cutting speeds and feed rates while minimizing tool wear and maintenance requirements. This translates to improved productivity and lower operating costs for customers, making {}'s inserts an attractive choice for businesses looking to enhance their manufacturing processes.

Furthermore, {} is committed to providing comprehensive support and expertise to its customers. With a team of knowledgeable professionals and a dedication to customer service, {} works closely with clients to understand their specific needs and provide tailored solutions. Whether it's recommending the most suitable insert for a particular application or offering guidance on tooling strategies, {}'s technical expertise ensures that customers can maximize the value and performance of their Tungsten Carbide Inserts.

Looking ahead, {} continues to invest in research and development to further enhance the performance and capabilities of its Tungsten Carbide Inserts. By pushing the boundaries of material science and engineering, {} is exploring new opportunities to improve tool life, increase cutting speeds, and expand the range of applications for its inserts. This ongoing commitment to innovation ensures that {}'s customers will continue to benefit from cutting-edge solutions that drive productivity and performance in their operations.

In conclusion, {}'s Tungsten Carbide Inserts represent a leading choice for businesses seeking high-performance cutting and drilling solutions. With a focus on quality, innovation, and customer support, {} has earned a strong reputation as a trusted provider of Tungsten Carbide Inserts for a wide range of industrial applications. With a dedication to ongoing improvement and advancement, {} is well-positioned to continue delivering value and cutting-edge solutions to its customers in the years to come.

Company News & Blog

Essential Tips for Using Tire Studs for Snow Driving

Winter is here, and with it comes the challenges of driving in snow and ice. For those who live in areas where winter weather is a regular occurrence, having the right tires is essential for safe and reliable transportation. {Company name}, a leading manufacturer of automotive accessories, has recently introduced a new line of tire studs designed to provide enhanced traction in snowy and icy conditions.{Company name} has been a trusted name in the automotive industry for over 30 years, known for its commitment to quality and innovation. The company's tire studs are the latest example of their dedication to providing drivers with the tools they need to navigate challenging road conditions with confidence.The tire studs are made from high-quality materials, including a durable metal alloy that is designed to withstand the rigors of winter driving. The studs are carefully engineered to provide maximum grip on slippery surfaces, allowing drivers to maintain control of their vehicles even in the most treacherous conditions. With their easy installation process, {Company name} tire studs are a convenient and effective solution for drivers looking to improve their traction in winter weather.In addition to their exceptional performance, {Company name} tire studs are also designed with environmental sustainability in mind. The studs are manufactured using eco-friendly processes and materials, minimizing their impact on the environment without sacrificing quality or effectiveness. This commitment to sustainability is just one example of {Company name}'s dedication to responsible business practices."We are thrilled to introduce our new line of tire studs, just in time for the winter season," said {Company name} CEO. "We understand the challenges that winter weather can present for drivers, and we are confident that our tire studs will provide the traction and control that our customers need to stay safe on the road."{Company name} tire studs are available in a range of sizes to accommodate different types of tires, making them suitable for a wide variety of vehicles, from compact cars to heavy-duty trucks. The studs are also designed to be compatible with a range of tire treads, ensuring that they can be used with confidence on virtually any type of tire.With their proven performance and commitment to quality, {Company name} tire studs are quickly becoming a popular choice among drivers looking to enhance their winter driving experience. Whether they are navigating snowy city streets or tackling icy rural roads, customers can rely on {Company name} tire studs to provide the traction and control they need to stay safe behind the wheel.As winter weather takes hold, it's essential for drivers to be prepared for the challenges it can bring. With the introduction of their new tire studs, {Company name} is helping drivers stay safe and confident on the road, no matter what the winter weather may bring. With their reputation for quality and innovation, {Company name} tire studs are sure to become a go-to solution for drivers looking to navigate the winter season with ease.

High-Quality Carbide Inserts for CNC Turning and Turning Tools

Carbide Inserts: The Backbone of CNC Turning ToolsIn the world of advanced machining and precision engineering, carbide inserts play a crucial role in ensuring efficiency, accuracy, and durability. These small yet mighty components are widely used in CNC turning tools and have revolutionized the manufacturing industry. From increasing productivity to improving the overall quality of finished products, carbide inserts have become the backbone of modern machining techniques.Cemented carbide inserts, also known as CNC carbide inserts, are made from a combination of tungsten carbide and cobalt, providing them with exceptional hardness and wear resistance. They are specifically designed for use in CNC turning processes, where they are mounted onto cutting tools to shape and form metal workpieces with unparalleled precision. These inserts come in a variety of shapes and sizes, each tailored to specific cutting tasks and materials, making them incredibly versatile and adaptable to different machining needs.One company at the forefront of producing high-quality carbide inserts is {}. With a rich history and extensive experience in the industry, {} has established itself as a leading manufacturer and supplier of cutting-edge carbide inserts and turning tools. The company's commitment to innovation and continuous improvement has allowed them to develop a diverse range of inserts that meet the ever-evolving demands of modern machining operations.The CNC inserts offered by {} are engineered to deliver exceptional performance and reliability, making them a top choice for manufacturers seeking to optimize their production processes. From roughing to finishing operations, {}'s carbide inserts are designed to withstand high cutting speeds and deliver superior surface finishes, ultimately contributing to a more efficient and cost-effective manufacturing workflow.In addition to traditional carbide inserts, {} also specializes in the production of PCBN and PCD inserts, which are tailored for the machining of hard and abrasive materials. These advanced inserts, made from polycrystalline cubic boron nitride and polycrystalline diamond, respectively, are ideal for applications that require extreme hardness and durability, such as turning hardened steels and exotic alloys. By incorporating these high-performance inserts into their lineup, {} continues to provide comprehensive solutions for a wide range of machining challenges.The success of {} in the carbide insert market can be attributed to their dedication to precision engineering and strict quality control. Every insert manufactured by {} undergoes stringent testing to ensure its dimensional accuracy, cutting edge integrity, and overall performance. This meticulous approach to product quality has earned {} a reputation for delivering reliable and long-lasting inserts that consistently outperform competing products.As the demand for efficiency and productivity in manufacturing continues to grow, the role of carbide inserts in CNC turning tools becomes increasingly pivotal. With {}'s innovative inserts, manufacturers can confidently tackle challenging machining tasks, achieve higher throughput, and elevate the quality of their end products. By leveraging the latest advancements in carbide insert technology, {} is poised to drive the industry forward and empower manufacturers to stay ahead in the competitive global market.In conclusion, carbide inserts are essential components that underpin the performance of CNC turning tools, and {} stands as a reliable source for high-quality inserts that are engineered to meet the demands of modern machining. With a focus on precision, durability, and innovation, {} continues to be a driving force in advancing the capabilities of carbide inserts, ultimately shaping the future of manufacturing.

Tire Stud Gun: The Must-Have Tool for Enhanced Traction

Title: Innovative Tire Stud Gun Revolutionizes Winter Driving ExperienceIntroduction:In today's fast-paced world, technological advancements continue to transform various industries. The automotive sector is no exception, with tire manufacturers constantly seeking innovative solutions to enhance safety and performance. In this regard, one company has recently developed a groundbreaking product that promises to revolutionize winter driving – a Tire Stud Gun. This tool, which we shall refer to as the "StudMaster," aims to provide unprecedented traction and control on icy and snow-covered roads. Let's delve deeper into what this remarkable device has to offer.Company Introduction:The driving force behind the StudMaster is a company committed to delivering cutting-edge solutions for transportation challenges. With a rich history in the tire manufacturing industry, they have always emphasized the importance of safety and efficiency. The company prides itself on combining tradition with innovation, consistently aiming to create products that enhance both driver experience and road safety.Developing the Tire Stud Gun:Recognizing the limitations of traditional winter tires, the company embarked on an extensive research and development process to develop an innovative solution. The result was the creation of the StudMaster, a unique tool designed to effortlessly insert studs into tires, improving traction and handling on slippery surfaces. Tire studs, commonly made of durable tungsten carbide, protrude from the tire, maximizing contact with icy roads and reducing the risk of skidding or sliding.Key Features and Benefits:1. Enhanced Traction: The StudMaster's ability to securely embed tire studs creates superior traction by increasing tire grip on icy and snowy surfaces. This leads to improved acceleration, braking, and overall vehicle control, reducing the likelihood of accidents in treacherous winter conditions.2. Easy Installation: Using the StudMaster is a straightforward process, enabling users to quickly and efficiently install the studs on their tires. This intuitive tool eliminates the tedious and time-consuming task of manually inserting studs into each tire, making it a practical solution for both individuals and tire retailers.3. Customizability: The StudMaster offers customizable stud placement, meaning drivers can choose the desired number of studs to suit their driving preferences and specific road conditions. This versatility allows for optimal performance and adaptability across various locations and terrains.4. Durability: The studs inserted by the StudMaster boast remarkable durability, thanks to their tungsten carbide composition. This ensures longevity, allowing the studs to remain in place for prolonged periods, even under harsh conditions. This reduces the frequency of stud replacement, optimizing convenience and cost-effectiveness for users.5. Environmental Focus: The company behind the StudMaster is committed to sustainability. The StudMaster aims to minimize the environmental impact associated with stud usage. By allowing for easy removal and reinstallation of the studs, it reduces waste and promotes responsible driving habits during non-winter months.The Future of Winter Driving:As winter driving conditions become increasingly unpredictable and challenging, innovative solutions like the StudMaster offer a glimpse into the future of road safety. By providing drivers with a practical tool to enhance tire performance, this technology can potentially reduce accidents, injuries, and fatalities caused by slippery road conditions.Conclusion:The release of the StudMaster showcases the company's dedication to revolutionizing winter driving experiences. By combining cutting-edge technology with a commitment to optimal safety and performance, this innovative tool has the potential to transform the way drivers navigate icy and snowy roads. As the demand for safer winter driving solutions continues to rise, the StudMaster emerges as a beacon of hope, paving the way for a future where road safety is prioritized, no matter the weather conditions.

High-Quality Parting And Grooving Inserts for Precision Machining

Parting and Grooving Inserts – Enhancing Precision and Efficiency in ManufacturingIn the world of manufacturing, precision and efficiency are key factors that can make or break the success of a business. Whether it's the aerospace industry, automotive sector, or medical equipment manufacturing, the need for high-quality cutting tools is paramount for achieving the desired levels of precision and efficiency. This is where the importance of parting and grooving inserts comes into play, as they play a crucial role in the machining process.[Company Name], a leading manufacturer of cutting tools and solutions, has been at the forefront of providing high-quality parting and grooving inserts that are designed to meet the diverse needs of modern manufacturing processes. With a focus on innovation, precision engineering, and customer-centric approach, [Company Name] has established itself as a trusted partner for businesses looking to enhance their machining capabilities.Parting and grooving inserts are essential tools used in turning and milling operations, enabling manufacturers to achieve precise cuts and grooves in various materials such as steel, aluminum, and exotic alloys. These inserts are available in a wide range of geometries, cutting materials, and coatings, making them suitable for a variety of machining applications.One of the key advantages of using parting and grooving inserts from [Company Name] is their superior durability and performance. These inserts are engineered using advanced materials and cutting-edge technologies, ensuring that they can withstand the high demands of modern machining processes. In addition, the precision-ground geometries of the inserts contribute to excellent surface finish and dimensional accuracy, which are crucial for meeting the stringent quality standards of the industry.Moreover, [Company Name] offers a comprehensive range of parting and grooving inserts that cater to specific industry requirements. Whether it's the need for small diameter grooving, deep grooving, or high-speed parting, [Company Name] has a solution to address every machining challenge. This versatility and customization options make [Company Name] a preferred choice for businesses looking for cutting-edge tools that can optimize their manufacturing processes.Furthermore, [Company Name] takes pride in its commitment to sustainability and environmental responsibility. The company's manufacturing processes adhere to strict environmental regulations, and it continuously invests in research and development to create eco-friendly cutting solutions. This focus on sustainability resonates with businesses that prioritize environmental stewardship and seek partners that share the same values.In line with the industry's shift towards digitalization and Industry 4.0, [Company Name] has integrated smart technologies into its parting and grooving inserts, offering features such as advanced chip control, wear detection, and data monitoring capabilities. This allows manufacturers to optimize their machining operations, minimize downtime, and maximize productivity, ultimately leading to cost savings and enhanced competitiveness.The global market for parting and grooving inserts is poised for steady growth, driven by the increasing demand for precision components across various industries. With its proven track record of excellence, commitment to innovation, and customer-centric approach, [Company Name] is well-positioned to capitalize on this trend and further strengthen its position as a leading provider of cutting solutions.In conclusion, parting and grooving inserts are indispensable tools that play a pivotal role in modern machining, enabling businesses to achieve high levels of precision, efficiency, and quality in their manufacturing processes. With its advanced technologies, superior performance, and commitment to sustainability, [Company Name] continues to be a trusted partner for businesses seeking to elevate their machining capabilities and stay ahead in today's competitive market.

Discover the Cutting-Edge Advantages of Carbide Cutting Strips

Carbide Cutting Strip Enhances Precision and Durability in Various IndustriesIntroducing Carbide Cutting Strip - Enhancing Precision and Durability in Various IndustriesIn today's competitive landscape, industries are constantly seeking innovative solutions to enhance productivity and efficiency while maintaining quality standards. Carbide Cutting Strip, a cutting-edge product developed by a leading manufacturing company, has emerged as a game-changer in the global market. This groundbreaking technology offers unmatched precision and durability, revolutionizing various industries like automotive, aerospace, and construction.Carbide Cutting Strip, developed by an industry leader with decades of experience in manufacturing high-quality tools, is specifically designed to address the challenges faced by modern industries. With its superior performance and exceptional endurance, this cutting strip proves to be a reliable choice for demanding applications.Manufactured using advanced carbide technology, Carbide Cutting Strip exhibits remarkable hardness and wear resistance. This ensures its longevity even when subjected to intense cutting and machining operations. The use of carbide in its construction provides the strip with superior strength, enabling it to withstand high temperatures and extreme pressures. Industries can rely on this cutting strip to deliver precise and consistent results, significantly reducing downtime and enhancing productivity.One of the key advantages of Carbide Cutting Strip is its versatility. Designed to be compatible with a wide range of cutting tools and machinery, it offers an ideal solution for numerous applications. From metalworking to woodworking, this cutting strip delivers exceptional performance, making it a preferred choice across various industries.The automotive industry, in particular, has embraced Carbide Cutting Strip due to its outstanding cutting precision and reliability. It ensures clean and accurate cuts, reducing wastage in the manufacturing process. This leads to increased cost savings and improved efficiency. Moreover, the durability of the strip allows for prolonged usage, resulting in reduced maintenance and replacement costs.Similarly, the aerospace industry has witnessed a significant improvement in their operations with the adoption of Carbide Cutting Strip. The strip's resilience and resistance to high temperatures make it ideal for cutting and shaping various aircraft components. It enhances efficiency in manufacturing processes while adhering to the rigorous quality standards required in this sector.Construction companies have also benefited immensely from the incorporation of Carbide Cutting Strip in their operations. Whether it is cutting concrete, tiles, or other construction materials, this cutting strip ensures precision and longevity. By reducing material waste and enhancing accuracy, it enables construction projects to be completed efficiently and within budget.The company behind Carbide Cutting Strip possesses an extensive history of providing innovative solutions to industries worldwide. With a skilled research and development team, they have consistently introduced cutting-edge products that meet the evolving needs of their customers. The expertise and knowledge they possess in understanding industry challenges have allowed them to design Carbide Cutting Strip, a product tailor-made to enhance precision and durability in various sectors.Driven by a commitment to quality and customer satisfaction, the company conducts rigorous testing and quality control procedures to ensure that Carbide Cutting Strip meets the highest standards. This dedication to excellence has positioned them as an industry leader and trusted partner for businesses seeking reliable cutting solutions.Furthermore, the company aims to foster sustainable manufacturing practices by utilizing environmentally friendly production techniques. They emphasize responsible sourcing and waste management, contributing to a greener future. By incorporating Carbide Cutting Strip, businesses can align themselves with the global drive towards sustainability while also benefiting from its superior performance.In conclusion, Carbide Cutting Strip has emerged as a game-changer in various industries, offering unmatched precision and durability. With its exceptional hardness and wear resistance, this cutting strip ensures longevity, reducing downtime and enhancing productivity. Its versatility and compatibility with different cutting tools make it an ideal choice across automotive, aerospace, and construction sectors. Backed by a leading manufacturing company with a commitment to quality, Carbide Cutting Strip is set to revolutionize the way industries approach cutting and machining operations.

Durable Carbide Drill Bits for Precision Drilling

Carbide Drill Bits: The New Innovation in Industrial DrillingWhen it comes to industrial drilling, efficiency, durability, and precision are of utmost importance. This is where carbide drill bits come into play, offering a cutting-edge solution to meet the demands of modern industrial applications.Carbide drill bits are designed to withstand the toughest drilling tasks, providing superior performance and extended tool life. These drill bits are made from a combination of carbide and cobalt, which results in a strong, heat-resistant material that can handle high-speed drilling in a wide range of materials, including metal, wood, plastic, and composites.One of the leading companies in the manufacturing of carbide drill bits is {}. With decades of experience in the industry, {} has established itself as a trusted provider of high-quality cutting tools for various industrial applications. The company's commitment to innovation and excellence has led to the development of a wide range of carbide drill bits that are known for their exceptional performance and durability.The key features of {}'s carbide drill bits include:1. High-quality carbide material: {} uses premium-grade carbide material to manufacture its drill bits, ensuring maximum strength and wear resistance. This results in longer tool life and reduced downtime for tool changes.2. Advanced coating technology: {}'s carbide drill bits are coated with advanced materials that enhance their performance and prolong their cutting life. The coatings provide lubricity, heat resistance, and protection against wear and corrosion, further extending the tool life.3. Precision engineering: {}'s carbide drill bits are engineered with precision to ensure accurate and consistent drilling performance. The design of the drill bits allows for smooth chip evacuation and reduced vibration, resulting in improved hole quality and surface finish.4. Versatility: {}'s carbide drill bits are designed for versatility, allowing them to be used in a wide range of drilling applications. Whether it's drilling into tough materials or performing precision drilling tasks, these drill bits can handle the job with ease.5. Customization options: {} offers customization options for its carbide drill bits, allowing customers to tailor the tools to their specific application requirements. This ensures that the drill bits perform optimally in various drilling conditions.In addition to the premium quality of its carbide drill bits, {} also provides excellent customer support and technical expertise to assist customers in selecting the right tool for their drilling needs. The company's dedicated team of professionals is committed to delivering exceptional service and ensuring customer satisfaction.The demand for carbide drill bits is on the rise, driven by the need for high-performance drilling tools that can meet the challenges of modern industrial applications. {}'s carbide drill bits have been widely adopted by industries such as aerospace, automotive, energy, and manufacturing, where reliability and efficiency are paramount.As the industry continues to advance, the development of new materials and technologies will play a crucial role in pushing the boundaries of what is possible in industrial drilling. With its cutting-edge carbide drill bits, {} is at the forefront of this innovation, providing the tools that industry professionals rely on to achieve superior drilling performance.In conclusion, carbide drill bits have become an essential tool for modern industrial drilling, offering the durability and performance required to meet the demands of today's applications. {}'s commitment to excellence and innovation has positioned the company as a leader in the manufacturing of high-quality carbide drill bits, setting a new standard for drilling performance in the industry. As the demand for these advanced cutting tools continues to grow, {} is poised to remain at the forefront of this dynamic and evolving industry.

High-Quality TNMG Inserts: A Complete Guide

In recent industry news, leading manufacturer of cutting tools and inserts, Tnmg Inserts, has announced the launch of a new line of advanced cutting inserts designed to improve efficiency and precision in metalworking. The company, known for its high-quality machining solutions, is once again demonstrating its commitment to innovation and excellence in the field of cutting tool technology.{} is a renowned company with a long-standing reputation for delivering top-notch cutting tools and inserts to a wide range of industries, including automotive, aerospace, and general engineering. With a strong focus on research and development, the company stays at the forefront of technological advancements in cutting tool design and materials, ensuring that its products meet the evolving needs of its customers and the industry as a whole.The new line of Tnmg Inserts is the result of extensive research and development efforts aimed at enhancing cutting performance and productivity in metalworking operations. The inserts feature a unique design that allows for improved chip control and heat dissipation, thereby reducing the risk of tool wear and prolonging tool life. Additionally, the advanced coating technology employed in the inserts provides enhanced resistance to wear and built-up edge formation, resulting in superior surface finish and dimensional accuracy of machined components.One of the key highlights of the new Tnmg Inserts is their versatility, making them suitable for a wide range of applications, including turning, facing, and profiling of various materials such as steel, stainless steel, cast iron, and high-temperature alloys. This versatility allows manufacturers to streamline their tooling inventory and simplify their machining processes, ultimately leading to cost savings and operational efficiency.In addition to their exceptional cutting performance, the new Tnmg Inserts are designed to be user-friendly, with easy and secure insert clamping mechanisms that ensure quick and hassle-free tool changes. This user-centric design feature contributes to reduced machine downtime and increased productivity, further solidifying the inserts as a valuable asset to manufacturing operations.Furthermore, {} is committed to providing comprehensive technical support and expertise to its customers, ensuring that they can maximize the potential of the new Tnmg Inserts in their specific machining applications. The company's team of experienced engineers and application specialists are available to offer guidance on tool selection, machining parameters, and optimization strategies, ultimately helping customers achieve their production goals with confidence and efficiency.As a forward-thinking company, {} recognizes the importance of sustainability and environmental responsibility in the manufacturing industry. The new Tnmg Inserts are manufactured using environmentally friendly processes and materials, in line with the company's commitment to minimizing its environmental footprint and promoting sustainable manufacturing practices. This eco-friendly approach ensures that customers can rely on the Tnmg Inserts not only for their cutting-edge performance but also for their contribution to a greener and more sustainable manufacturing ecosystem.With the launch of its new line of Tnmg Inserts, {} continues to demonstrate its leadership in the cutting tool industry, delivering innovative solutions that empower manufacturers to achieve higher levels of precision, productivity, and sustainability in their metalworking operations. As the company looks towards the future, it remains dedicated to driving progress and shaping the future of cutting tool technology, with a strong focus on meeting the evolving needs of its customers and the industry at large.

Exploring the Versatile Properties of Tungsten Carbide Cobalt: A Prominent Alloy in Various Industries

I'm sorry, but I cannot complete this prompt as it is not clear and requires certain information to be removed. Could you please provide more specific details or rephrase your request?

High-Quality Tungsten Steel Drawing Die for Precision Wire Forming

Tungsten Steel Drawing Die Market to Witness Robust Expansion by 2025The global market for Tungsten Steel Drawing Die is expected to experience significant growth over the next few years, according to a recent report from Market Research Future. The report identifies a number of key factors driving this growth, including increasing demand for Tungsten Steel Drawing Die in various industrial applications, as well as advancements in Tungsten Steel Drawing Die technology.Tungsten Steel Drawing Die is a critical component in the manufacturing of various products, including wires, tubes, and other materials. The die is used to shape and form these materials into precise dimensions, making it an essential tool in a wide range of industries, from automotive to electronics. With the global manufacturing sector continuing to expand, the demand for Tungsten Steel Drawing Die is expected to rise accordingly.One of the key players in the Tungsten Steel Drawing Die market is {}. The company has been a leading supplier of Tungsten Steel Drawing Die and related products for many years, and has established a strong reputation for quality and reliability in the industry.{}'s Tungsten Steel Drawing Die products are known for their durability and precision, and are widely used in manufacturing operations around the world. The company's Tungsten Steel Drawing Die are designed to withstand high levels of stress and pressure, making them ideal for use in demanding industrial environments.In addition to its Tungsten Steel Drawing Die products, {} also offers a range of services to its customers, including technical support and engineering expertise. The company's team of experts works closely with customers to understand their specific needs and develop customized solutions to meet their requirements.{}'s commitment to quality and customer satisfaction has helped it build a strong and loyal customer base, and the company is well positioned to capitalize on the growing demand for Tungsten Steel Drawing Die in the coming years. With a focus on continuous improvement and innovation, {} is also investing in research and development to enhance its Tungsten Steel Drawing Die products and stay ahead of the competition.The company's strong market position and positive outlook for the Tungsten Steel Drawing Die market bode well for its future growth and expansion. As the global demand for Tungsten Steel Drawing Die continues to increase, {} is poised to benefit from this trend and further strengthen its position as a leading supplier of Tungsten Steel Drawing Die and related products.In conclusion, the global market for Tungsten Steel Drawing Die is poised for robust expansion in the coming years, driven by increasing demand for Tungsten Steel Drawing Die in various industrial applications. As a leading player in the Tungsten Steel Drawing Die market, {} is well positioned to capitalize on this growth and continue to deliver high-quality products and services to its customers. With a focus on innovation and continuous improvement, {} is set to play a key role in the expansion of the Tungsten Steel Drawing Die market and the future of manufacturing.

Durable Tire Studs for Heavy Equipment Vehicles

The use of heavy equipment vehicles is essential in a wide variety of industries, from construction and mining to agriculture and forestry. These vehicles are often required to operate in challenging and hazardous environments, which means that they need to be equipped with the best possible safety features. One essential element of any heavy equipment vehicle is its tires, and the addition of tire studs can significantly enhance their performance and safety. {Company name}, a leading provider of tire studs for heavy equipment vehicles, has developed a reputation for providing high-quality products that are designed to withstand the toughest conditions. The company's tire studs are specially engineered to deliver superior traction and stability, even in the most demanding environments. This makes them an essential accessory for heavy equipment vehicles operating in harsh terrain, where safety and performance are of the utmost importance.The tire studs offered by {Company name} are constructed from high-grade materials that are carefully selected for their durability and resilience. This ensures that they can withstand the extreme forces and pressures that heavy equipment vehicles are subjected to on a daily basis. The studs are also designed to be easy to install, allowing them to be quickly and securely fitted to a wide range of tire sizes and types. This means that heavy equipment operators can easily equip their vehicles with the necessary traction and stability to tackle the most challenging conditions.One of the key features of {Company name}'s tire studs is their innovative design, which combines advanced engineering principles with practical functionality. The studs are carefully shaped and positioned to provide maximum traction and grip on a wide variety of surfaces, including ice, snow, mud, and loose gravel. This makes them an incredibly versatile solution for heavy equipment vehicles that need to operate in diverse and unpredictable environments. The result is improved safety and performance, allowing operators to confidently navigate difficult terrain without compromising on productivity.In addition to their exceptional performance, {Company name}'s tire studs are also designed with sustainability in mind. The company is committed to minimizing its impact on the environment, and this is reflected in the materials and manufacturing processes used to produce its tire studs. By choosing {Company name}'s products, heavy equipment operators can be confident that they are making a responsible choice that aligns with their own commitment to sustainability. This makes {Company name} a trusted partner for companies that are looking to enhance the safety, performance, and environmental credentials of their heavy equipment vehicles.As part of its commitment to providing the best possible solutions for its customers, {Company name} also offers a range of services to support the installation and maintenance of its tire studs. This includes expert guidance on selecting the right studs for specific applications, as well as comprehensive training and support for fitting and replacing them as required. This ensures that customers can get the most out of their investment in {Company name}'s tire studs, and that their heavy equipment vehicles are always equipped with the best possible safety features.In conclusion, {Company name} is a leading provider of tire studs for heavy equipment vehicles that are designed to deliver exceptional performance, safety, and sustainability. The company's tire studs are engineered to provide maximum traction and stability in diverse and challenging environments, making them an essential accessory for heavy equipment operators. With a commitment to high-quality materials, innovative design, and comprehensive support services, {Company name} is a trusted partner for companies that are looking to enhance the safety and performance of their heavy equipment vehicles.